Movip

Modeling van Initiele Product Kwaliteit

Modeling of Product Initial Quality (MoViP)

Movip was an initiative to develop a methodology of predicting the product quality during the design phase. For this project a number of OEM's (ASML, Philips Healthcare, Thermo Fisher Sceintific (Fei), Kulicke & Soffa (Assembleon), knowledge institutes (IMEC, TNO) and a number of suppliers (Prodrive, TBP/Technolution, Neways, Variass, KMWE, NTS, CCM, Sioux, MI-Partners, Fibreworks and Bicore) delivered the backbone of the Product Quality Prediction Model (MoViP).

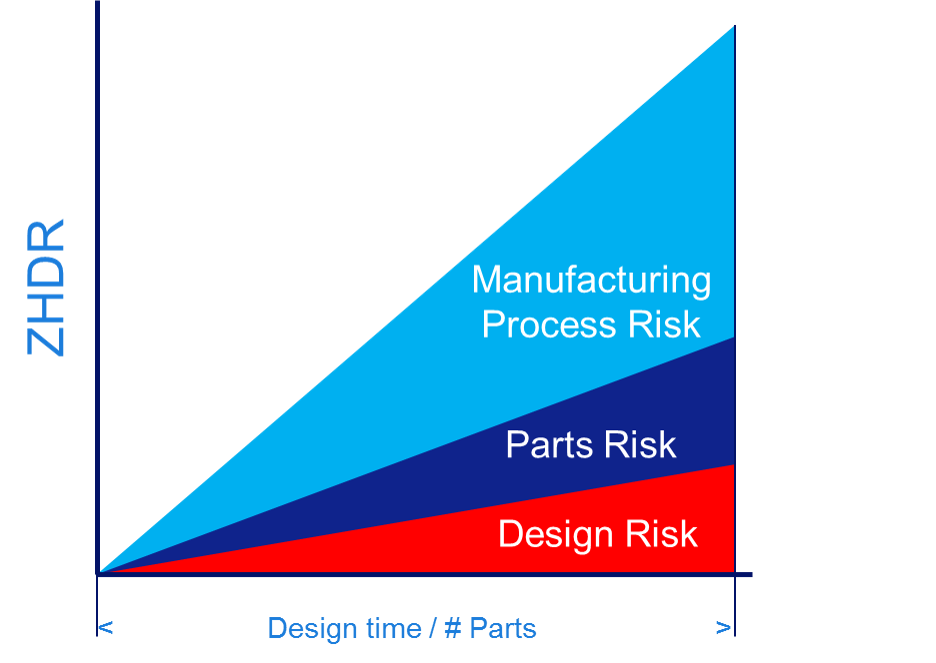

Measure of Product Quality (ZHDR)

When manufacturing products its evident that the risk of a failure increases with increasing the number of parts. This number of failures is a measure of the Zero Hour Defect Rate (ZHDR) of a product. Zero Hour Defect Rate (ZHDR) reflects the number of products which fail at the customer, with respect to the number of products delivered to the customer during an agreed period of time. A “failure” is the unplanned occurrence that prevents the product from meeting its functional requirements under the specified operating conditions.

The time period in which a product fails is the Infant Mortality of the reliability curve.

The other areas of the reliability, ie random failure mode and wear out, are not influenced by the manufacturing but by the design and use.

Product Design Failure Modes

When designing a product its evident that the risk of a failure increases with increasing the number of parts and/or design complexity.

Risk increases with #Parts

To determine the manufacturing caused failures (reliability infant mortality rate) of the product the traditional methods such as pFMEA's, early design involvement, building prototypes, process Fumo's or ... works well for products manufactured in large quantities and not having the pressure of fast market introduction. When manufacturing low quantities these methods helps but are costly and time consuming and doesn't help in cost price or market introduction. For industries in this category a methodology is developed to identify the manufacturing, part and process risks, during the design phase. Furthermore this methodology is based on historical part and process data gathered in the past and used to predict the expexted quality behaiour of the new designed part.When designing a product there are only three failure modes (Parts, Processes and the Design) which contributes to the "Non" Quality of a product.

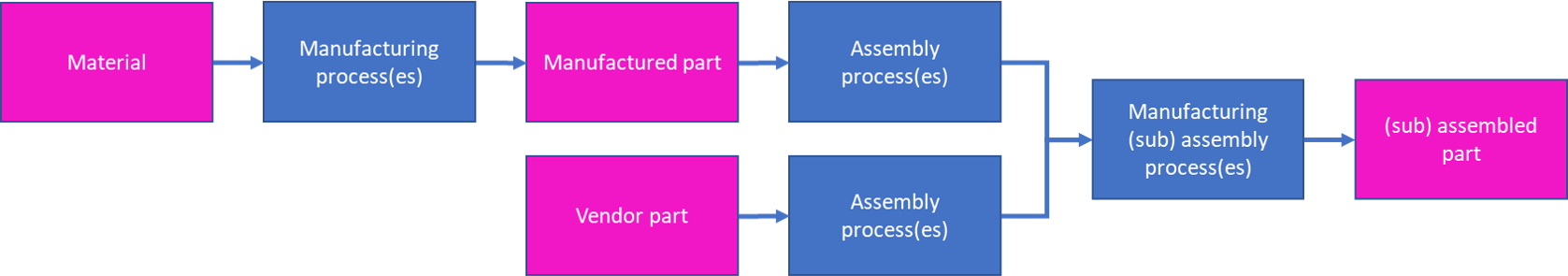

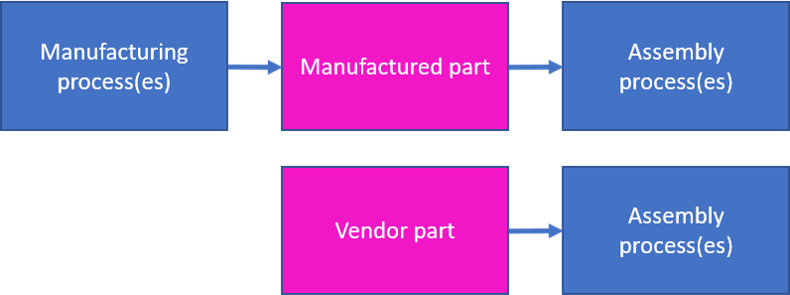

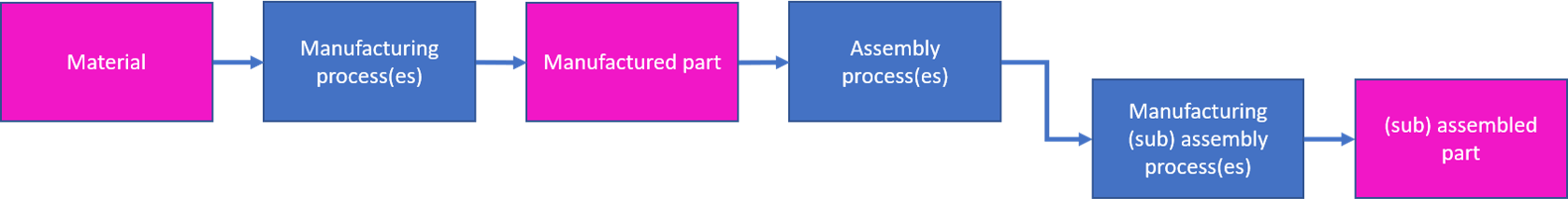

Parts are either vendor parts which are bought, manufactured parts which started with a material and ends up as a part manufactured according a drawing or assembled parts.

Processes are either the manufacturing processes (material -> part) or the assembly processes where vendor and manufactured parts put together lead to sub assembly(s) with in the end a product.

A design is the combination of parts when put together correctly deliver the required functionality.

Even when perfectly manufactured a product can fail or works for a limited time.

These failures are not caused by manufacturing and belongs to the design (reliability random failures) or belogs to the product use (reliability wear out failures).

These failures can only be avoided by a design change and not a manufacturing improvement.

Manufacturing caused failure modes are:

Possibly as third failure mode handling and transport are sometimes mentioned. This can be easely seen as a process where a part is packed, handled, stored or transported (process).

Failure Modes

Processes are always coupled to a part (vendor, manufactured or (sub)assembly). Based on this the Bill of Materials (BoM) contains everything to identify the part risks and based on the coupling of processes to a part also all process risks. Each part and the coupled processes based on the BoM result in a Zero Hour Defect Rate (ZHDR) when multiplied statistical correct.

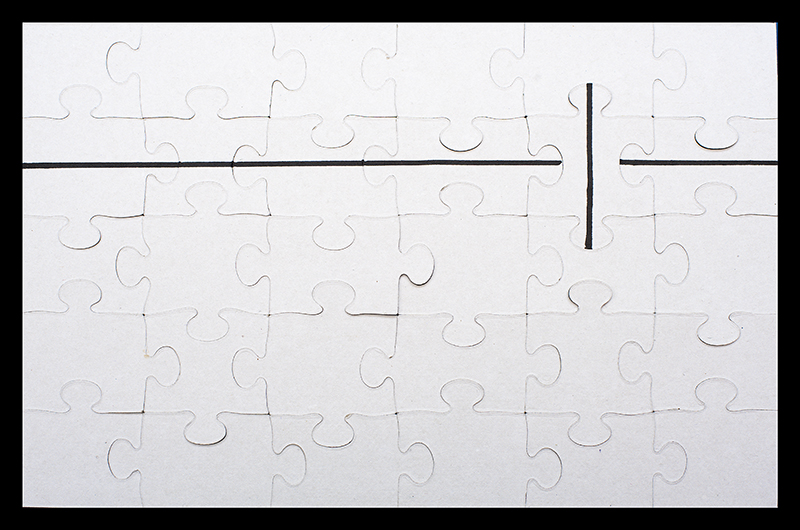

Part Process Relation

The risks of a failure per part or process is based on the failure rate history of that part or process. To identify the risk of failure for the part or proces(es) a part or process contains a number of failure modes.

Part-Process building blocks

Part and Process Faulure Modes:

Part Failure Modes

Vendor Part

Part Failure Modes:

Part Defect

A part is defect when the part is not functioning at all.

Examples: Hard disk is not functioning at all, a motor is not rotating.

Part Defect

Part Physical out of Spec

Part is not conform the physical specifications. This can be a large number of physical defects.

- Hole is missing

- Hole is not threaded

- Surface is scratched

- Surface is dented

- Part is not clean

- Part has bend legs (Integrated Circuit)

- ...

Example: Hard disk is either dented, scratched, has no threaded holes for mounting, connect broken, motor axis bend,...

Part Physical out of Spec

Part Functional out of Spec

Part functions not conform specification but is still working.

- Motor turns slower than specified

- Transmission lens is lower than specified

- Bandwidth/noise is not within specification

- ...

Example: Hard disk turn slower than specified rpm, access time slower,...

Assembly Failure Modes

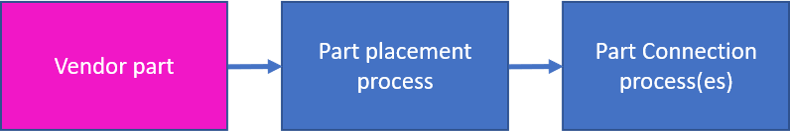

Assembling is building together one or more vendor parts with one or more manufactured parts to create a new part ((sub)assembly or even product). The assembly process consist of two process steps (placement and connection). When creating a (sub)assembly or product each vendor or manufactured part must be placed. Connection takes only place when the part connects one to another part (screw, glue, bond,...).

Assembly Failure Modes

Assembly Processes

Part Placement Risks

First step in the assembly process is always the placement of the parts. Risks of placing the part in the (sub)assembly are forgetting the part, using the wrong part, misplace the part, place the part with the wrong orientation, damaging the part during placement or places more parts than mentioned in the BoM.

Part Placement Risks

- Missing Part

- Wrong Part

- Misoriented Part

- Misplaced Part

- Part is damaged during placement

- Excess Parts

Missing Part

The risk that a part is not placed in the assembly.

Examples:

- Washer is missing

- O-Ring is missing

- Electronic parts missing on a Printed Circuit Board (PCB)

- Cover missing

- ...

Missing Part

Wrong Part

Another part is placed in the assembly than specified in the Bill of material (BoM)

Examples:- Wrong electronic component (value) in a Printed Circuit Board Assembly (PCBA)

- Magnetic fasteners where non magnetic fasteners are required

- Bolt length

- ...

Wrong Part

Misoriented part

Part is placed with the wrong orientation in the assembly.

Examples:- Inside out

- 90° rotated

- ...

Misoriented Part

Misplaced Part

The part is not mounted on the specified position.

Misplaced Part

Part is damaged during placement

Part is damaged during placement. How bigger the part how easier the damage occurs. This is also true if a part is fragile.

Examples:- Sheet metal

- Enclosures

- ...

Excess parts

More parts are placed in the product than identified on the BoM.

Examples:- Washers

- O-Rings

- ...

Part Connection Risks

Second step in the assembly process is connecting the parts together. Risks of connecting the part in the (sub)assembly not according specification. (screw not tigtening according torque, glue step not resulting in required strenght, connector misplaced,...

Part Connection Risks

Missing Connection

Risk of not connecting at all.

Examples:- No glue dispenced

- Cable or hose not connected at all (hanging loose)

- ...

Misplaced Connection

Risk of connecting at the wrong place.

Examples:- glue dispenced on wrong position

- Cable or hose connected at the wrong place

- ...

Misoriented Connection

Risk of connecting in the wrong orientation.

Examples:- Cable connected in the wrong orientation (3W3 sub D connector)

- ...

Connection process

Risk of not correct connecting.

Examples:- Screw not tightened according specified/requirred torque

- Cable not connected correctly

- Glue not according specified/required strenght

- Solder not according IPC

- ...

Part is Misconnected

Note: Handling, storing, transport or packaging of parts can be seen as an assembly process and threated as such.Manufacturing Failure Modes

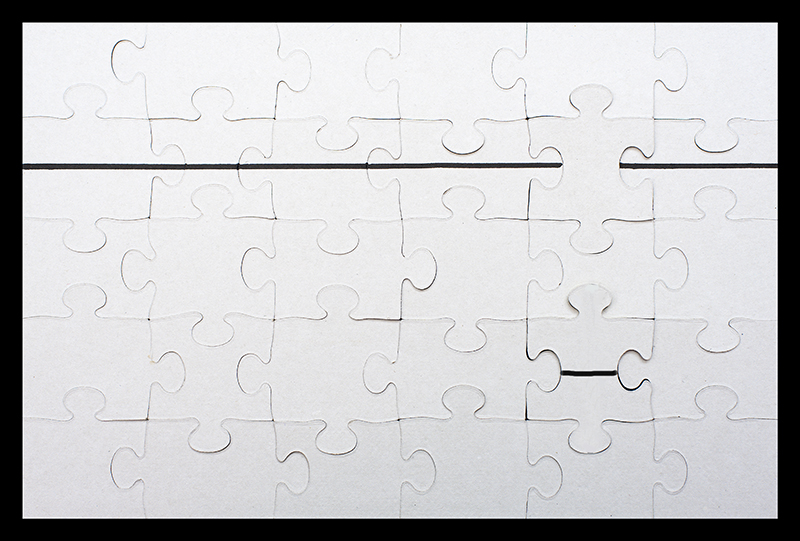

Manufacturing processes are either the manufacturing (milling, driling, surface threatment, ..) of a part or the common process(es) which lead to a (sub)assembly. Common process(es) can be seen as manufacturing process(es) of a (sub)Assembly.

Manufacturing Processes

Manufacturing Processes

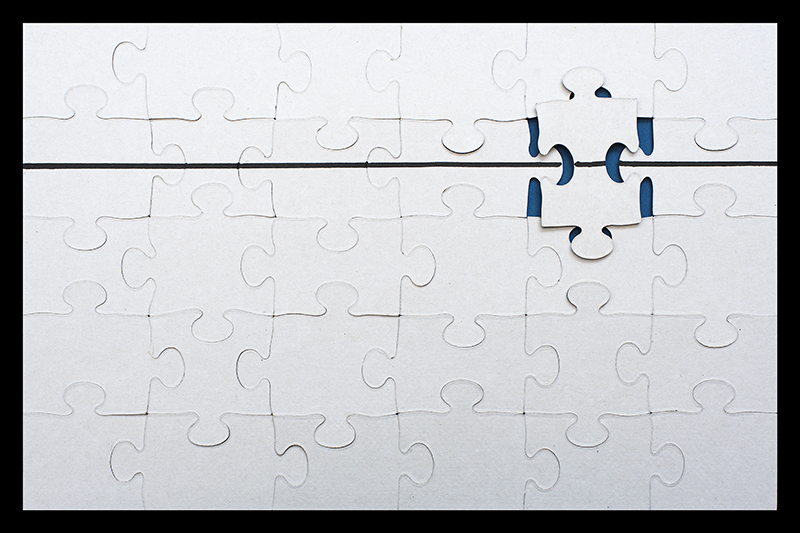

Manufacturing Process Manufactured Part

Manufacturing processes of a part are processes executed in a predefined sequence. Each manufacturing process contributes to the risk of not meeting the required manafuctured part quality. Where in assembly DPMO's or ppm's are used as measure of the risk in manufacturing the Cpk, Ppk, sigma's are also used. When for each manufacturing step the Cpk, Ppk or sigma's are known these can be easely translated to DPMO's.

Manufacturing Processes

Manufacturing Processes are:

- Mill

- Drill

- Thread

- Surface Threatment

- ...

The manufactured part risk is noting more than the material riks and the 'added' process risks. The material risk can be treated as a vendor part risk without any process associated to it. For the manufacturing process risk the same failure modes as in the connection process are used. These are the missing manufacturing step, wrong manufacturing step, manufacturing process risk or more processes used than agreed in the work flow.

Manufacturing Process (sub)Assembly

Last step in the assembly process before it is a (sub)assembly or product are the processes which are common to all previous assembled parts.Common Manufacturing (sub)Assembly

- Cleaning

- Testing

- Adjusting

- .....

These processes are for all parts in the (sub)assembly the same and are associated to the (sub)assembly as a manufacturing process. For the manufacturing process risk the same failure modes as in the connection process are used. These are the missing manufacturing step, wrong manufacturing step, manufacturing process risk or more processes used than agreed in the work flow.

Note: Design failures such as worst case designs are threated as manufacturing sub(assembly) failures.Determine Product Risk

To be able to calculate the product Zero Hour Defect Rate (ZHDR) for each failure mode a risk on occuring must be known.

For calculation purpose the Defect Parts per Milion Opportunities (DPMO) is used.

DPMO's are widely used or could be calculed from the Cpk, Ppk or sigma's.

When all DPMO's which can occur are known a product risk calculation can be done.

In practice every vendor part has 3 failure modes (part defect, part physical out of spec and part functional out of spec) and each part (vendor, manufactured or (sub)assembly) has at least 1 process associated.

Manufactured parts have the material and all processes which are used to manufacture the part.

(sub)Assemblies can have also manufacturing process(es) associated to it.

This means a maximum of 6 failure modes (missing, wrong, misplaced, misoriented, process and excess parts/processes) where every failure mode has a corresponding DPMO.

ZHDR Calculations

This calculation result in a product ZHDR where the DO (Defect Opportunities or failure modes) has a corresponding DPMO.

ZHDR can be either in % DPMO or ...

The DPMO correspond to the manufacturers capability for that specific part or process failure mode. Based on this product ZHDR a list can be created which shows the largest contributors of the part and processes. This list is the starting point of the Risk Mitigation.

Risk Mitigation

Before mitigation of the risk it's good to know the required part quality in ZHDR. With other words what is needed to succesfully build and use the product. When having calculated the Zero Hour Defect Rate (ZHDR) based on the manufacturers capability and this is larger than the required product ZHDR there are three options to lower the ZHDR.

![]()

ZHDR Specified/Calculated

Design change is the first step in mitigation. Based on the list of part or process risks a design change must be made which avoids those risks. When not possible the second best option is to improve the processes which contribute most to the high ZHDR of the product. Last resort is to test the remaining risks which could not be solved with a design change or process improvement. Realize that a test when its detect a failure it will result in a scrap action and as such increasing the cost price.

Mitigation scenarios

Design Change

Select out of the list of risks those parts and/or processes which contribute to not meeting the product ZHDR. For parts a replacement with a less risk part or avoidance of that part is the only way to improve. For processes another design which avoids those processes is the solution.

Process Improvement

When a design change is not sufficient to meet the product ZHDR process improvemnt is the next option.

![]()

ZHDR Specified/Calculated

In an assembly process, even with skilled/trained operators, perfect workinstructions, sign off lists, ideal environment or ... incidents happen. To avoid these process incidents the process must be controlled in itself. The most easy way is automating the process, or put in other words avoid manual labour. Worldwide is manual labour a risk. To get a feeling for the contribution of manual labour an average incident rate is 1000ppm (1 of the 1000).When manufactured part processes contributes to not meeting the product ZHDR those identiefied process must be improved. When manual labour with manufactured part is the contributor the process must be improved. When there is no manual labour which can be improved an other strategy can be another machine or again avoid a process risk by relaxing the requirement which causes the risk.

Test

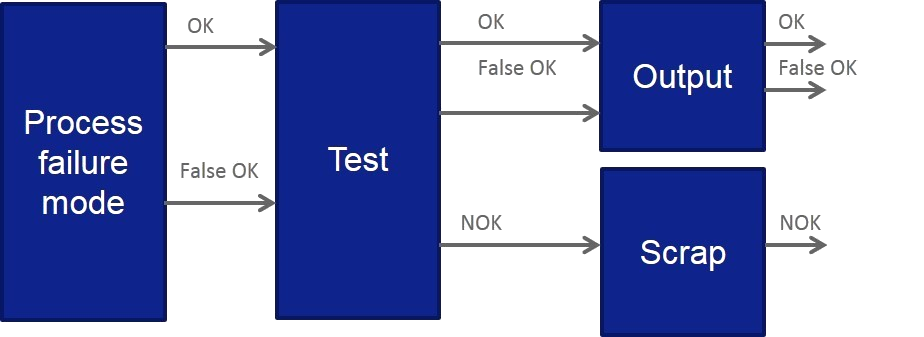

Even when the design changes and process improvements are not sufficient to meet the product ZHDR the last resort is testing.

![]()

ZHDR Specified/Calculated

Each part or process which is tested and is Not Ok results in scrapping the product. When testing not on product level but on part or (sub)assembly level the consequences are the same but the cost involved is lower.

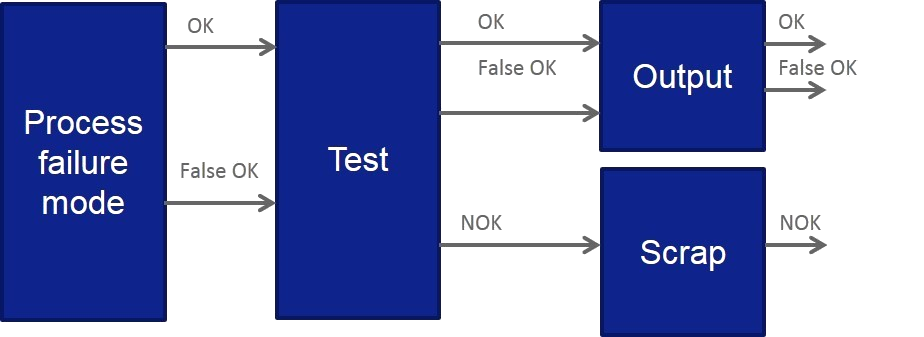

Process & Test resulting in OK/FOK/NOK

Calculation of the Zero Hour Defect rate (ZHDR) includes now the test coupled to the defect opportunity.

ZHDR Calculations including test

For the test the slip (S) is defined as:

0 > No slip (no failure slips through)

1 > No test (all failures slips through to next stage)

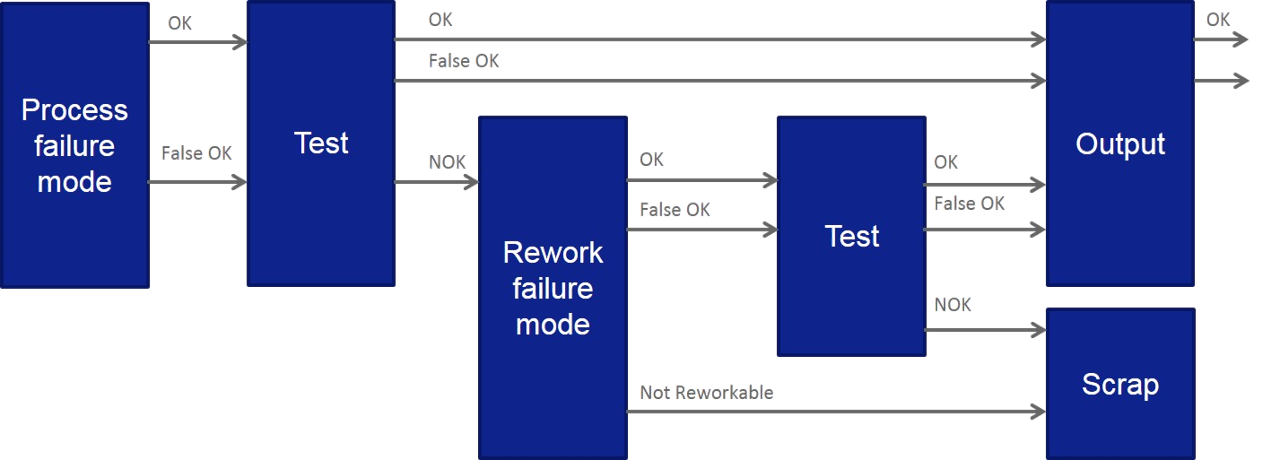

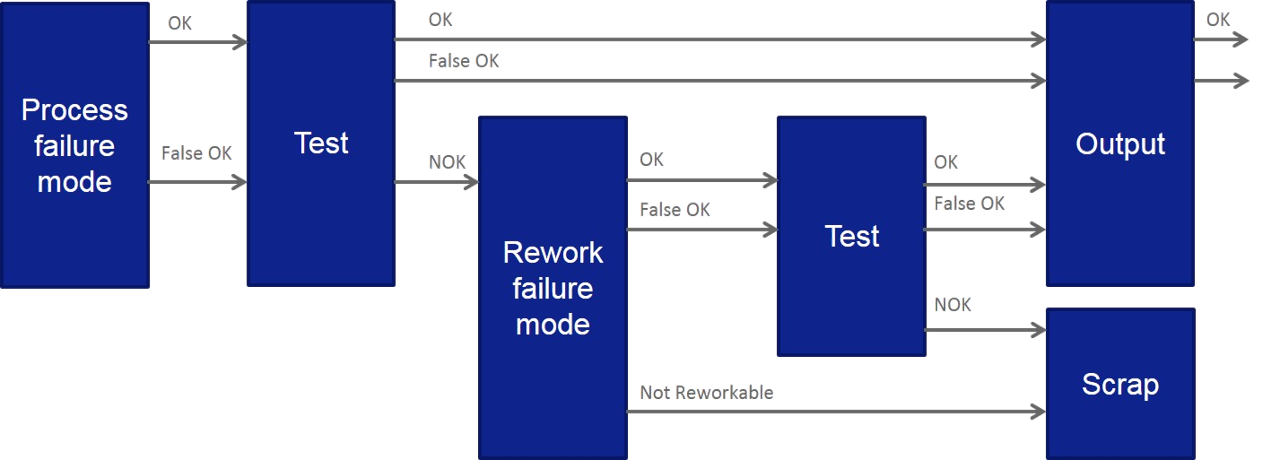

When testing identifies a NOK this sometimes can be reworked. When reworked this can solve the NOK but also can introduce new risks. Testing the reworked product is mostly done on another test fixture than the test used for production.

ZHDR Calculations including test & rework

ZHDR Calculation

When not reworking the formula is correct and can be cascaded where the output OK is the input of the next process. The false Ok's and the NOK are added with the output of the previous process. The rule used is that when false Ok or NOk it is not be possible that it will become OK again.

ZHDR Calculations including test

The calculation model is without rework.

Process & Test resulting in OK/FOK/NOK

When reworking the basics stay the same but the NOK will be rework to a Ok. This is not always possible and will stay NOK and scrapped. But parts which are reworkable will undergo a process which again introduceds risks. The output again will be tested. The output again will create an reworked Ok, a reworked false Ok and a reworked NOK. These outputs will be added to the Ok, false Ok and scrapped outputs.

ZHDR Calculations including test & rework

Without rework it is possible to calculate the ZHDR by putting all failure modes behind each other with the (sub)assembly part DPMO's set at 0. When reworking parts a more elaborate method has to be followed and the BoM hierarchy has to be observed. This means that BoM Level for level has to be determind starting at the lowest level in the build hierarchy.

- Part Risks

- Mounting Risks

- Connection Risks

- Assembly Process Risks

When the DPMO's vary outside a limited band use the formula below

All these Defect Opportunity (DO) corresponding risks together, give an insight in which risk contributes most to the Zero Hour Defect Rate (ZHDR) of the assembly.

Contributors:

- Part Risks

- Mounting Risks

- Connection Risks

- Assembly Process Risks

Hierarchy

With complex assemblies the build sequence is mostly done in a hierarchical way. When encountering such a hierarchy each hierarchical level results in itself in a part with all the part, mounting, connection and assembly related risks. This part is treated as a part one hierarchical level up. When out of the design phase the build sequence is done in takts and can be treated the same way as a hierarchy.

Hierarchical connections

When connecting cables, hoses (fluids, gasses, vacuum, ..), this could be treated as a separate hierarchical level. The cable, hose in itself is treated as a part with a risk and as a connection with its connection risks. This methodology is needed to avoid counting risks more than once.

Printed Cicuit Board Assemblies (PCBA) connections

When connecting Printed Circuit Board Assemblies (PCBA) to each other, counting the risk more than once is not allowed. An approach could be to select the male or female connectors for determining the connection risk.

Risk Mitigation

![]()

If it is specified that a product requires a Zero Hour Defect Rate (ZHDR) of 1000ppm (1 of 1000 may fail) the risks must be mitigated to reach the specified Zero Hour Defect Rate. Starting point are the largest contributors of the Zero hour Defect Rate (ZHDR). Mitigation can be done in three ways.

Design Change

Avoiding the risks is the best way to mitigate. If the design can be changed in such way that the risks are avoided then this is to most preferable way of mitigation.

With the changed design, the calculation must be repeated with the new Bill Of Material (BOM) and/or the changed connections and/or the changed assembly process. The recalculated Zero Hour Defect Rate (ZHDR) must be checked if it is within specification.

Part Related Risk Mitigation

Part risks are design related due to the fact that the Bill Of Material (BOM) is dictated by design. Part related risks can only be mitigated by changing those parts which contributes to the Part related Zero Hour Defect Rate (ZHDR).

Mounting Related Risk Mitigation

Avoiding mounting risks is done by at least following the rules of Designing For Manufacturing (DFM), Designing For Assembly (DFA) and respecting the industrialization rules. Yang, Kai, Design for Six Sigma, Chapter 10 (10 Tien-Chien Chang, Richard A. Wysk, and Hsu-Pin Wang. Computer-Aided Manufacturing, Second Edition, Pages 596 to 598 (11

- Develop a modular design

- Use of standard parts

- Minimize number of parts

- Minimize number of different parts

- Use only one type of fastener, resistor, capacitor,.... (Wrong)

- Minimize adjustments

- Make adjustment accessible

- Design parts to be multi-functional

- Design for ease of manufacturing

- No symmetrical mounting (Misoriented)

- Minimize assembly directions

- Use gravity when mounting parts

- Use no hand tools

- Minimize handling

Connection Related Risk Mitigation

Mitigating connection risks is done by avoiding those connection technologies in the design which contributes most to the connection related Zero Hour Defect Rate (ZHDR).

Assembly Processing Related Risk Mitigation

Mitigating assembly processing risks is done by not using these assembly processing technologies in the design which contributes most to the assembly processing related Zero Hour Defect Rate (ZHDR).

Calculate New Zero Hour Defect Rate (ZHDR)

Based on the design changes a new Bill Of material (BOM) is created and the Zero Hour Defect Rate (ZHDR) must be (re)calculated.

This results in a new Zero Hour Defect Rate (ZHDR) which must be checked if the Zero Hour Defect Rate (ZHDR) is within specification.

![]()

Manufacturing Process Change

When the design changes alone are not sufficient to reach the specified Zero Hour Defect Rate (ZHDR), the risks in the manufacturers process can be mitigated.

Part Related Risk Mitigation

The only exception which can't be mitigated in the manufacturing process are the part related risks. These can only be mitigated in the design, so only the mounting, connection or assembly process risks can be mitigated by changing/improving the manufacturing process.

Mounting Related Risk Mitigation

Mitigation of only the contributing mounting risks in the manufacturing process are required. (good is good) The categories in the calculated Zero Hour Defect Rate (ZHDR) are missing, wrong, misoriented, misplaced and must lead to a change in the manufacturing process to minimize the risk.

Examples of mitigation strategies are :- Missing (poka-yoke, lean process, ..)

- Wrong (logistics)

- Misoriented (poka-yoke, lean process, ..)

- Misplaced (poka-yoke, lean process, ..)

Connection Related Risk Mitigation

Improving of only the contributing connection risks in the manufacturing process are required. The category in the calculated Zero Hour Defect Rate (ZHDR) is connection and must lead to a change to minimize the risk.

- Screw (process improvements, Tools,...)

- Glue (process improvements, Tools,...)

- Solder (process improvements, Tools,...)

- Press (process improvements, Tools,...)

- Bond (process improvements, Tools,...)

- Rivet (process improvements, Tools,...)

- Staple (process improvements, Tools,...)

- ....

Assembly Processing Related Risk Mitigation

Improving of only the contributing assembly processing risks in the manufacturing process are required. (good is good) The categories in the calculated Zero Hour Defect Rate (ZHDR) are coating, cleaning, excess parts, adjusting, testing, greasing, ... and must lead to a change in the assembly process to minimize the risk.

- Coating (improve process,...)

- Cleaning (improve process,...)

- Excess parts

- Adjusting

- Greasing

- Testing

- .....

Calculate the New Zero Hour Defect Rate (ZHDR)

Based on the Manufacturing process change new processes are used and the Zero Hour Defect Rate (ZHDR) must be (re)calculated.

This results in a new Zero Hour Defect Rate (ZHDR) which must be checked if the Zero Hour Defect Rate (ZHDR) is within specification.

![]()

Testing

Testing is the last resort which must be used when the design or manufacturing process changes are not sufficient to reach the required Zero Hour Defect Rate (ZHDR). Testing will always brings added risk, scrap, rework, cost and time by introducing testers.

Part Related Risk Mitigation

Part risks are design related due to the fact that the Bill Of Material (BOM) dictates these parts. Part related risks, which are not mitigated by a design change, needs to be tested to reduce those Part related Zero Hour Defect Rate (ZHDR).

- Part Defects (Incoming inspection, Test in assembly, ....)

- Part physical out of specification (Incoming inspection, Test in assembly, ....)

- Part functional out of specification (Incoming inspection, Test in assembly, ....)

Mounting Related Risk Mitigation

Mounting risks are manufacturing process related and can only be tested during or after assembly.

- Missing (Test in assembly, ....)

- Wrong (Test in assembly, ....)

- Misoriented (Test in assembly, ....)

- Misplaced (Test in assembly, ....)

Connection Related Risk Mitigation

Connection risks are assembly process related and therefore tested during or after assembly.

- Screw (test, ...)

- Glue (test, ...)

- Solder (test, ...)

- Press (test, ...)

- Bond (test, ...)

- Rivet (test, ...)

- Staple (test, ...)

- ....

Assembly Processing Related Risk Mitigation

Assembly process risks are manufacturing process related and therefore tested after assembly.

- Coating (test, ...)

- Cleaning (test, ...)

- Excess parts (test, ...)

- Adjusting (test, ...)

- Greasing (test, ...)

- .....

Test Mitigation

Each part, mounting, connection or assembly processing risk can be mitigated with a test. Each implemented test can influence one or more risks (defect opportunities) or one or more parts.

For this the variable Slip is a measure of how much the risk is mitigated.

If the slip is 1 no mitigation takes place.

If the slip is 0 the risk is completely mitigated.

![]()

Mitigated Zero Hour Defect Rate (ZHDR) Calculation

The part, mounting, connection and assembly process risks (DPMO's) are multiplied with the corresponding part, mounting, connection and assembly process slip.

This results in a new Zero Hour Defect Rate (ZHDR) which must be checked if the Zero Hour Defect Rate (ZHDR) is within specification.

![]()

Design Failure Contributions

Methodologies to get insight in the design failures early in the design phase (architecture) is a Design Failure Mode Effect Analasys (DFMEA) where based on experiences of the past risks are identified. These risks can be quantized in a Zero Hour Defect Rate (ZHDR). New designs where there is no experiences have a high risk and those risks should be avoided or get insight in the risks by building a functional model. Furthermore each specification must be guaranteed by design or a test must be created to ensure this specification. When the design is finished a design verification must be done which must at least verify al the specifications. The same methodology also applies here that when a specification is not met a test must be applied to secure the specification. Underneath the DFMEA, Specification calculation and verification are the part and design related risks.

This could be caused by either a part or the design, even when the design is assembled correctly, resulting in not meeting the specifications.

Part Related Risks

A part could be used outside its specified area.

A special case is when the part is used outside its Safe Operating Area which causes wear and affects the reliability on long term. This will be explained in Life Time Risks.

- Part used outside specified area

- Usage of non specified part behaviour

- Part stress (internal, external mounting, thermal,..)

Part used Outside Specified Area

When a part is used outside its specified area the part is itself is correct but its usage not. Due to the not specified behaviour it is possible that the assembly will fail.

Examples:

- Sensor linearity

- Lens aberrations/transmission outside specified area

Usage of non specified Part Behaviour

All parts, even with the most extensive documented specifications, have hidden performances which are not guarantied.

Examples:

- OpAmp Noise behaviour is only specified for low frequencies

- Optical elements specifeid on optical axis

- ...

Design Related Risks

When assembled, the tolerances of all parts could lead to an assembly out of specification. (Worst case Risks)

- Timing violations (digital circuits)

- Noise behaviour (analog circuits)

- Offset (Sensor + acquisition system)

- Build dimensions (mechanic parts)

- Stress induced mounting

- Stress induced by thermal cycling during opteration. (Infant mortality)

- ....

Mitigate Part or Design related Risks

Mitigation of the part or design risk is possible by either changing the design or selecting other parts so the risks are avoided.

Calculate the New Zero Hour Defect Rate (ZHDR)

Based on the design changes a new Bill Of material (BOM) is created and the Zero Hour Defect Rate (ZHDR) must be (re)calculated.

When a design change is not possible, the design must be tested on the risks to make sure that no part which could fail reaches the customer.

The same methodology also applies for the design related risks as for the assembly related risks. A test must be applied on the risks and the test slip multiplied with the risk DPMO.

Mitigated Zero Hour Defect Rate (ZHDR) Calculation

The Zero Hour Defect Rate (ZHDR) design risks are multiplied with the corresponding slip of the applied test.

This results in a new Zero Hour Defect Rate (ZHDR) which must be checked if the Zero Hour Defect Rate (ZHDR) is within specification.

Handling and Transport Failure Contributions

Handling Related Risks

Assemblies are handled to go to a storage area or packaging area.

- Electro Static Discharge (ESD)

- Packaging Risks

- Storage risks

Transport Related Risks

- Transport damage risks

Calculate the New Zero Hour Defect Rate (ZHDR)

Based on the changes in the handling and transport process the Zero Hour Defect Rate (ZHDR) must be calculated.

Mitigated Zero Hour Defect Rate (ZHDR) Calculation

The Zero Hour Defect Rate (ZHDR) handling and transport risks are multiplied with the corresponding slip.

This results in a new Zero Hour Defect Rate (ZHDR) which must be checked if the Zero Hour Defect Rate (ZHDR) is within specification.

Life Time Failure Contributions

Infant Mortality Related Risks

Random Life Time related risks

Structural Life Time related risks

Wear Life Time related risks

- Heat

References

(2 Yield

(3 Mcarthy, Thomas. The Six Sigma Black Belt Handbook, p. 307. 2004 McGraw Hill Education. ISBN10: 0071443290

(4 Througput Yield (TPY)

(5 Rolled Throughput Yield (RTY)

(6 Lunau, Stephan. Design for Six Sigma + Lean Toolset, p. 133. 2009 Springer-Verlag Berlin Heidelberg. ISBN 978-3-540-89513-8.

(7 Institute for Interconnecting and Packaging Electronic Circuits(IPC) IPC-7912A

(8 Yang, Kai, Design for Six Sigma, Chapter 11 2003 McGraw Hill, ISBN: 0-07-141208-5

(9 Mcarthy, Thomas. The Six Sigma Black Belt Handbook, p. 383. 2004 McGraw Hill Education. ISBN10: 0071443290.

(10 Yang, Kai, ''Design for Six Sigma'', Chapter 10 2003 McGraw Hill, ISBN: 0-07-141208-5

(11 Tien-Chien chang, Richard A. Wysk, and Hsu-Pin Wang. Computer-Aided Manufacturing, Second Edition, Pages 596 to 598. Prentice Hall 1998

(12 The bathtub Curve and Product Failure Behaviour (Part1)

(13 The bathtub Curve and Product Failure Behaviour (Part2)

Litirature on Quality

George, Michael l., ''What is Lean Six Sigma'', 2003, McGraw Hill, ISBN-10: 007142668X

George, Michael l., ''The Lean Six Sigma Pocket Toolbook'', 2004, McGraw Hill, ISBN-10: 0071441190

Morgan, John, ''Lean Six Sigma For Dummies'', 2012, Wiley Publishing, Inc., ISBN-10: 1119953707

Gygi, Craig, ''Six Sigma for Dummies'', 2005, Wiley Publishing, Inc., ISBN: 0-7645-6798-5

Webber, Larry, ''Quality Control for Dummies'', 2012, Wiley Publishing, Inc., ISBN-10: 0470069090

Kemp, Sid, ''Quality Management Dymistifeid'', 2006, McGraw Hill Education, ISBN: 0-07-144908-6